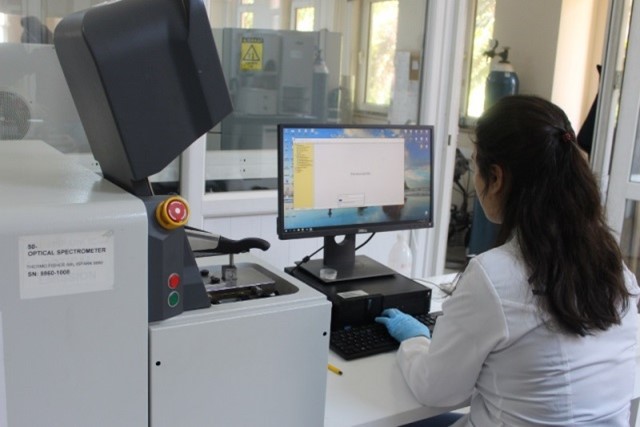

CHEMICAL ANALYSIS LABORATORY

Using the tools of our age technology; Before and after production, the chemical compositions of metallic materials and various raw materials are determined in this laboratory in order to determine the production method and to ensure the quality control of the produced materials. Our students gain the skills to analyze, interpret and report these analyzes by determining the appropriate characterization method before they start working as engineers.

Devices in Chemical Analysis Laboratory:

- X-Ray Fluorescence (XRF) Elemental Analysis

- Optical Spectrometer

- Hydrogen Analyzer

- Carbon Sulfur Determination Device

- Thermal Analysis (DSC-TGA)

- Titrimetric Analysis Equipment

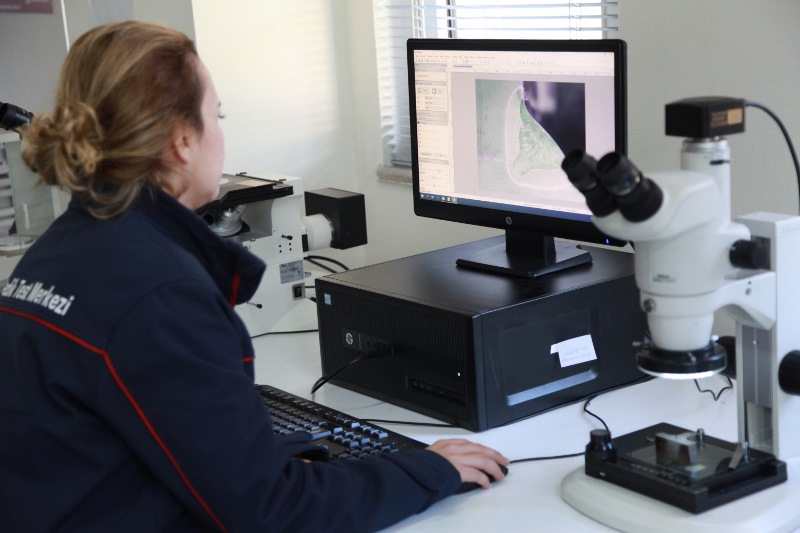

METALLOGRAPHY and HYDROMETALURGY LABORATORY

The most important parameters that determine the use performance of materials are the micro and macro structures of the material. The whole of the processes applied to the materials in order to determine the micro and macro structures and the subsequent microscope examinations are called metallography. Especially today, metallography processes are applied in almost every business in the metal industry in order to determine the quality of the product produced. While in the past, services were procured from certain laboratories in this regard, today each enterprise establishes its own metallography laboratory and interprets the results it obtains and determines its production and sales policies. For this reason, we attach great importance to our students who will work as engineers in their education life, especially in sample preparation, which requires experience, and structure interpretation, which requires knowledge of metallurgy and materials. In our laboratory, micro and macro structure examination, interpretation and reporting of the results are carried out with the help of both our sample preparation devices and microscopes. In addition, processes such as refining and metal recovery from wastes are carried out in this laboratory, together with hydrometallurgical metal production processes that are used in material production from raw materials, that come to the forefront with the use of low-grade ores and their environmental friendliness, providing high yield metal production.

Devices in Metallography Laboratory:

- Abrasive Cutting Device

- Hot Molding Device

- Vacuum Cold Molding Device

- Sanding – Polishing Device

- Fume Hood

- Optical Microscope (with Image Analyzer)

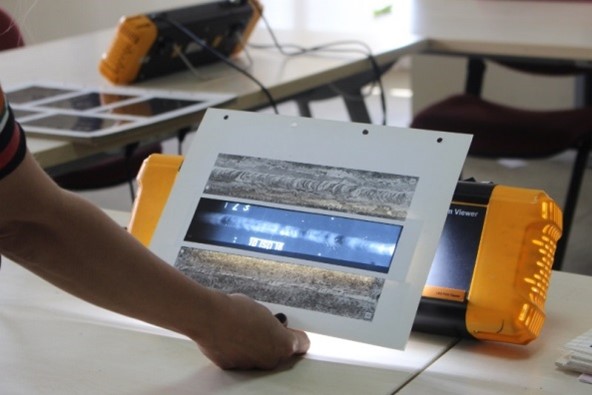

- Macro Imager (With Image Analyzer)

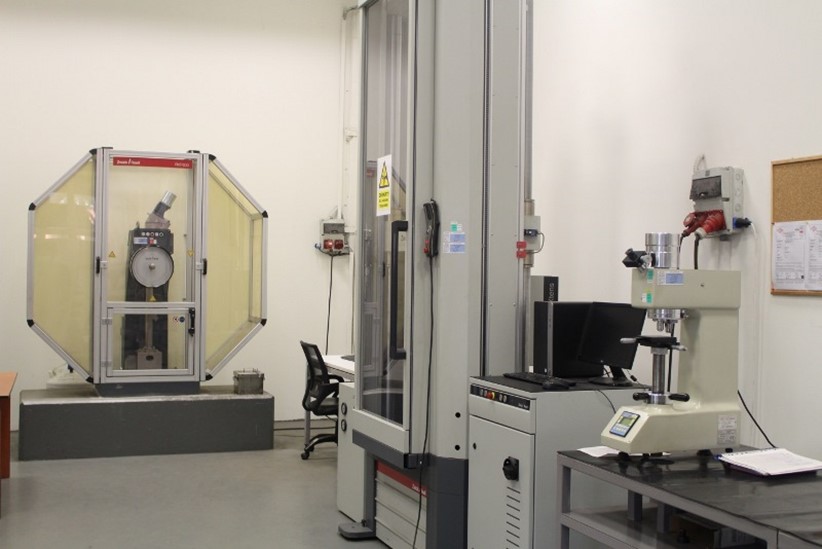

MECHANICAL TEST LABORATORY

One of the most important parameters in the design and selection of materials according to the area to be used is their mechanical properties. After all material production processes, mechanical properties such as strength, hardness and impact resistance are determined within the scope of certain standards as an indication that the material will meet the expected mechanical performance. In this sense, tensile test, hardness test and notch impact tests are carried out in fully accredited mechanical test laboratories and the results are reported. These tests and their results, which are applied or evaluated in the entire metal industry, are carried out by our students in our laboratories under the supervision of expert academics and personnel. Thus, our students can gain sufficient experience in the application and reporting of the methods they will encounter most in the sector when they graduate.

Devices in the Mechanical Test Laboratory:

- Vickers Hardness Tester

- Tensile Tester

- Notch Impact Tester

NON DESTRUCTIVE EXAMINATION LABORATORY

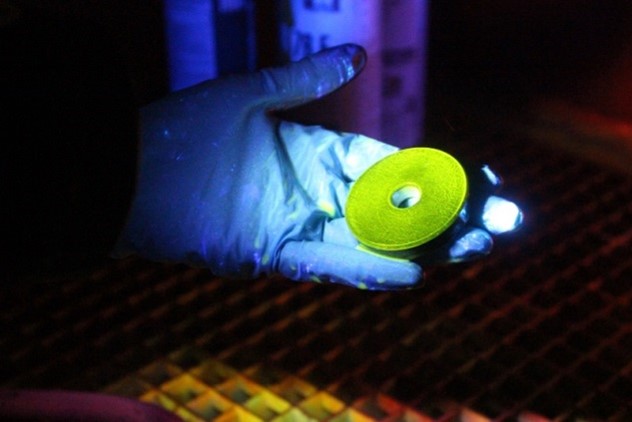

Non-destructive testing methods are used to determine damage, error or deformation without causing any damage to the material after the production or use of the materials. While companies in the sector received services from accredited companies in the past, many companies are establishing their own non-destructive testing laboratories and employing expert personnel in this regard. In this sense, before graduating, our students gain experience in applying these methods and interpreting and reporting their results. All non-destructive testing methods such as Visual Inspection, Liquid Penetrant Inspection, Ultrasonic Inspection, Radiographic Inspection and Magnetic Particle Inspection can be applied by our students in our accredited laboratory.

WELDING APPLICATION LABORATORY

Internationally valid welding engineering trainings are also carried out at undergraduate level in the realization of welding processes and examination of welded structures, which is one of the widest application areas of the metal sector. In our accredited laboratories, our students have the opportunity to apply all kinds of Tungsten Inert Gas Welding (TIG), Metal Inert Gas (MIG), Metal Active Gas (MAG), Electric Arc, Oxy-Acetylene, Resistance Spot and Submerged Submerged Welding methods and perform their metallurgical evaluations.

CHEMICAL-MATERIALS LABORATORY

In the Chemistry-Materials Laboratory within the body of Metallurgical and Materials Engineering, experimental applications that provide students with the chemistry infrastructure that they will use during their education are shown. Our students can reinforce their theoretical knowledge gained in the course curriculum in the laboratory environment with experiments. In this process, laboratory safety lesson is given to our students before starting the laboratory lessons. Chemistry-Materials Laboratory is used in the applications of Electrometallurgy, Corrosion and Protection, Polymer Materials, Ceramic Materials and Heat Treatment courses as well as Chemistry applications.